We would love to hear from you!

Feel free to reach out using the contact form to the right. Someone will reach out to you after receiving your submission.

In the message box please let us know some details about the project, what services you are looking for and a good time to contact you.

You can also contact Walt 3D LLC using the phone number below! If no answer please leave a message or feel free to send a text/email as well!

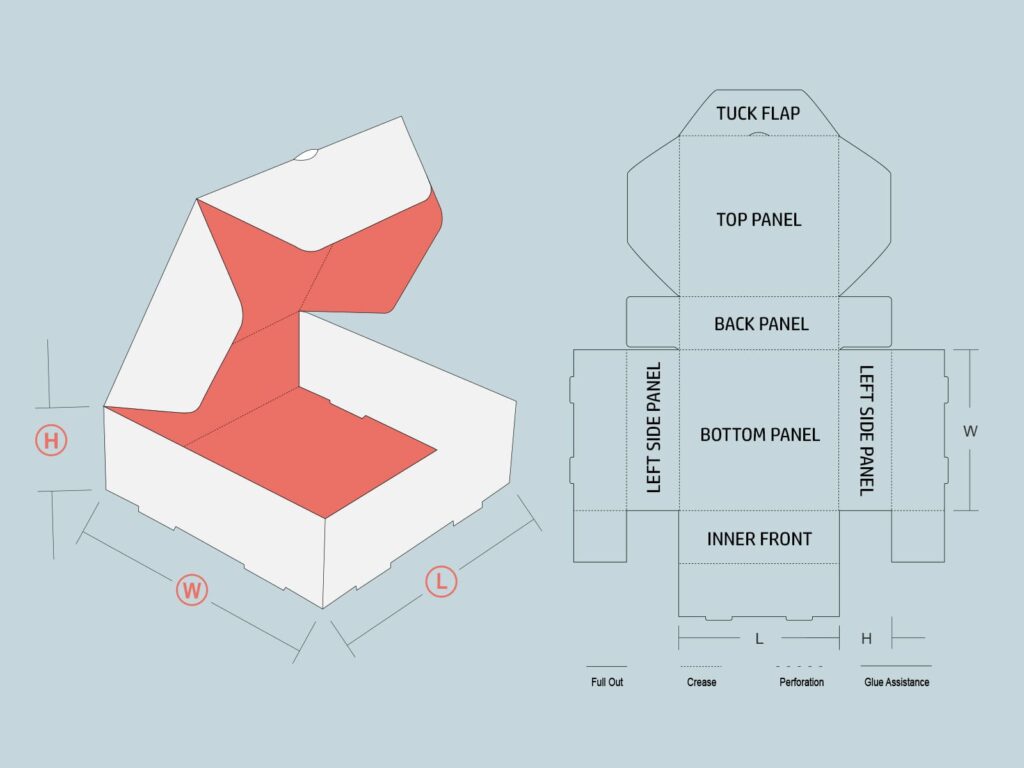

Packaging design or product packaging design refers to the creation of the exterior of a product, but can also refer to the interior components that stop parts from moving around or rattling during transport. Looks are often times just as important as function and when both are combined in a unique way, great things can occur. The result is a product presentation that looks good and protects the parts inside.

Packaging is used very loosely as there are a lot of types of packaging and applications that we can assist with. When it comes to packaging Walt 3D can assist in the design, prototype making and production of packaging made from cardboard, foam and plastics.

A CNC router is a type of computer controlled machine created for milling, drilling and cutting materials. CNC routers are similar to milling machines, with some of them capable of performing almost the same tasks. The main functions are to cut, engrave and carve objects out of a work piece, essentially a replacement for the usual hand-held router. By introducing computer control to the process, the number of errors is drastically reduced.

Concrete is the second most-used substance in the world after water. This is a very amazing fact about this material that many overlook. Concrete is similar to metal and plastic in that it can be extruded and cast into a variety of shapes.

While we do not offer concrete parts production, we are able to provide complimentary parts and accessories for the concrete industry. Parts and materials that we are able to make are profiles for concrete extrusion, molds for casting parts, and stamping patterns when finishing the surface of concrete pours. There are likely many more ways in which our design and production capabilities can be used in the concrete industry.

Carbon fiber is a high-performance material with a wide range of uses in manufacturing. It is lightweight with high stiffness and tensile strength, and low thermal expansion. At Walt 3D we are able to provide design and production assistance for the manufacturing and processing of carbon fiber parts. There are a multitude of techniques for producing parts made from carbon fiber and we have the knowledge and resources to produce these parts from a variety of these methods.

In general there are three main ways to process carbon fiber parts which include: Wet Lay-up, Prepreg Lamination and Resin Transfer molding. Keep in mind carbon fiber parts can also be CNC machined by cutting flat sheets, and even produced in extruded profiles.

While 3D Printing is generally used during the design and prototype making stages, it is sometimes necessary to produce production parts via this process. 3D printing is often the right manufacturing process for parts that are very low production volume, need to be produced in a short period of time or have very complex geometry not suitable for traditional manufacturing processes.

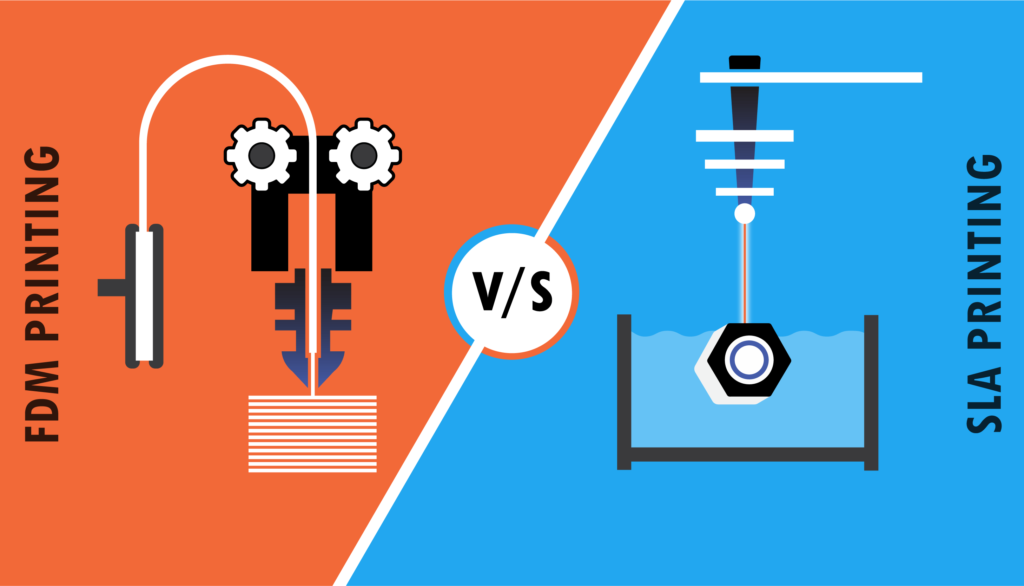

The two main types of 3D printing we work with are FDM 3D printing, the traditional filament on a spool, and SLA 3D printing, also known as resin 3D printing. Each process has its unique pros and cons. To learn more about what process might be right for your project feel free to contact us!

Liquid injection molding (LIM) is a fabrication process that uses special molds and injection molding machines to form liquid silicone materials into a broad range of components and products. Unlike the common reaction injection molding process that relies on pressurized impingement mixing, liquid injection molding uses a metered mechanical mixing process that is used primarily with liquid silicone rubber (LSR) and similar liquid-state elastomeric materials. These parts can be used in a variety of applications and offer exceptional part clarity when making clear parts.

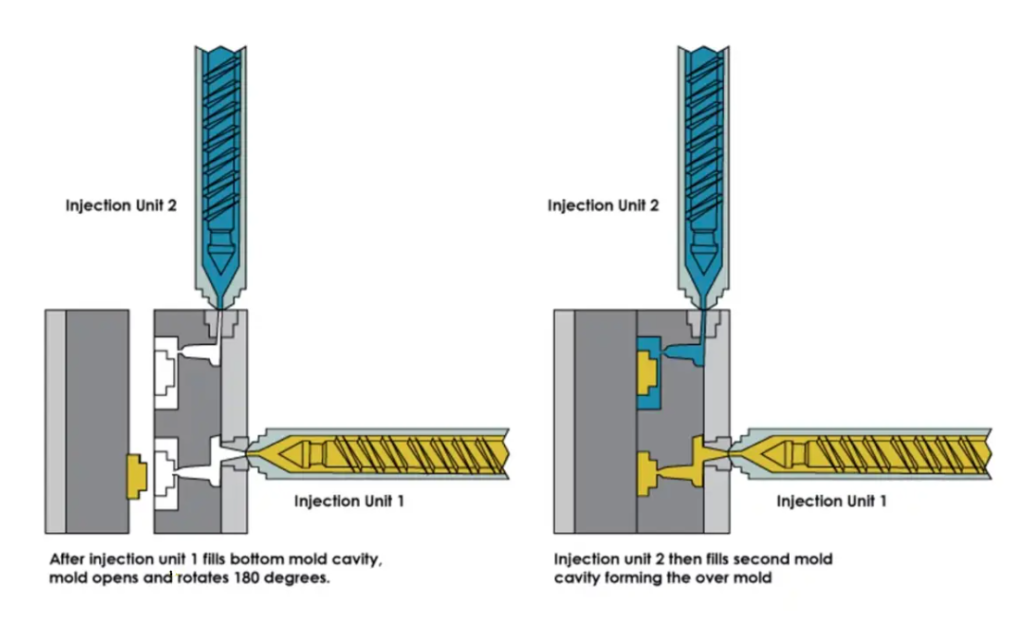

First, a base component (otherwise known as a substrate) is molded and allowed to cure. Overmolded substrates are often made of plastic. Then, a second layer is molded directly on top of the first to create a single solid piece. Overmolding is commonly used to manufacture plastic parts that feature a rubber handle. The two-shot process of over molding a toothbrush, for example, consists of forming a base layer for the plastic handle and a top layer of rubber (to make the toothbrush less slippery to hold).

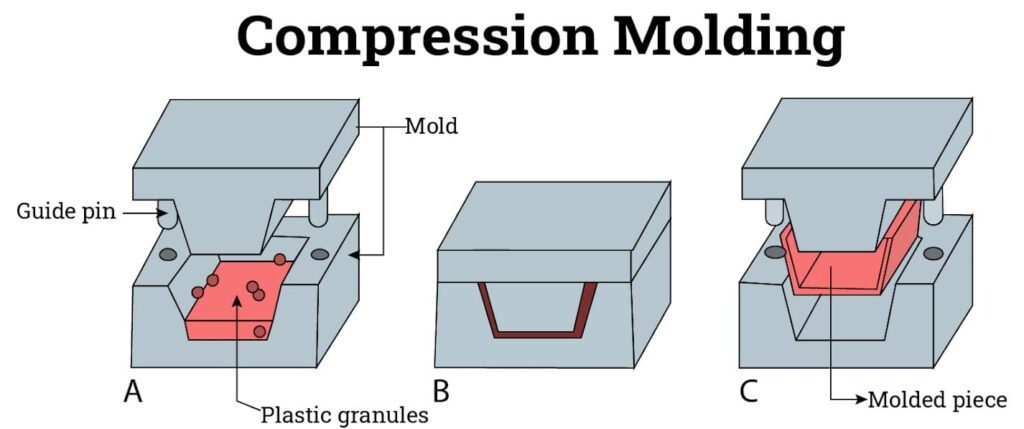

Compression molding and injection molding are very similar, but they have one major difference. In compression molding, molds are closed around the charge, and in injection molding, the charge is injected into a closed mold cavity.

Compression molding produces parts by placing a pre-measured amount of material into a mold, closing the tool, and applying heat and pressure. This pre-measured material is called a charge or load, and the mold is usually pre-heated so that the material flows more readily and fills the tool as it’s compressed. When molding is complete, the part is cooled, ejected, and trimmed or de-flashed.

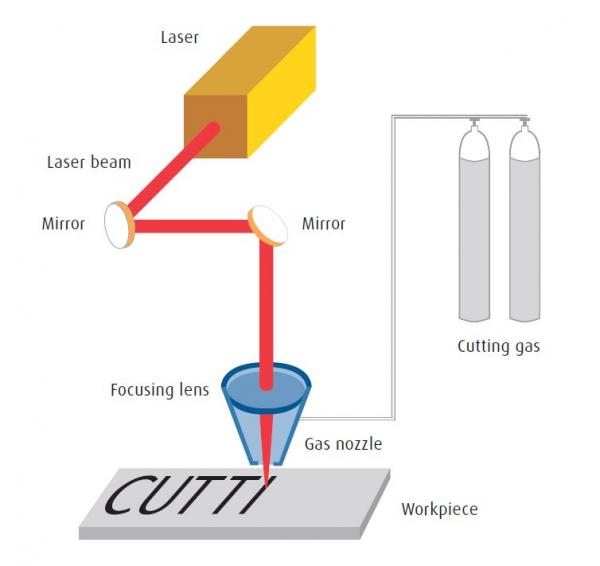

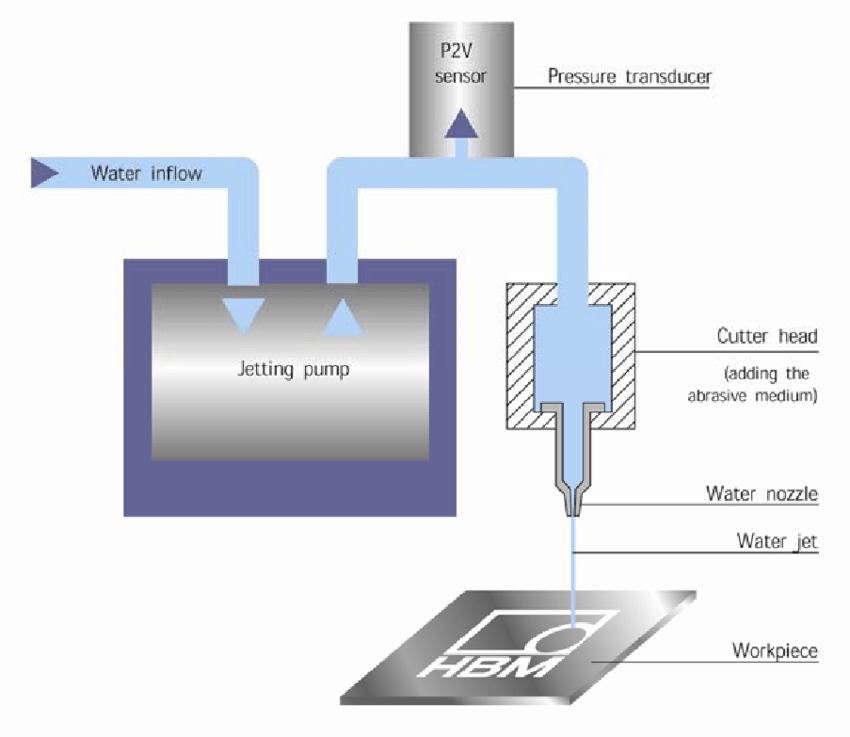

Both waterjet cutting and laser cutting are CNC controlled. Both are highly versatile and offer a high rate of accuracy and precision. They produce minimal waste, offer quick delivery, and are high-quality due to advanced software and superior equipment. Both processes are ideal for a wide number of industries including the aerospace, architecture, automotive, manufacturing, medical science, and power industries.

Waterjet cutting is generally the first choice when working with thicker and harder materials due to its high-pressure capacity. On the other hand, laser cutting is generally faster than waterjet cutting and offers a higher rate of precision. Laser cutting is the more cost-efficient option and is capable of cutting parts faster than waterjet cutting. In addition, a laser cutting machine is capable of cutting as well as engraving material; a waterjet only allows cutting.

Plastic machining is one of the most common industrial processes due to the high usage of this material. However, modern-day plastic CNC machining isn’t what it used to be. Plastics nowadays can be built strong enough to stop a bullet’s impact. This calls for a very rugged machining method.

CNC machining plastics has become a great solution for these requirements. Plastics have a lot of variety, with differences in physical properties and chemical structure. All of these varieties are easy to machine with CNC machining.

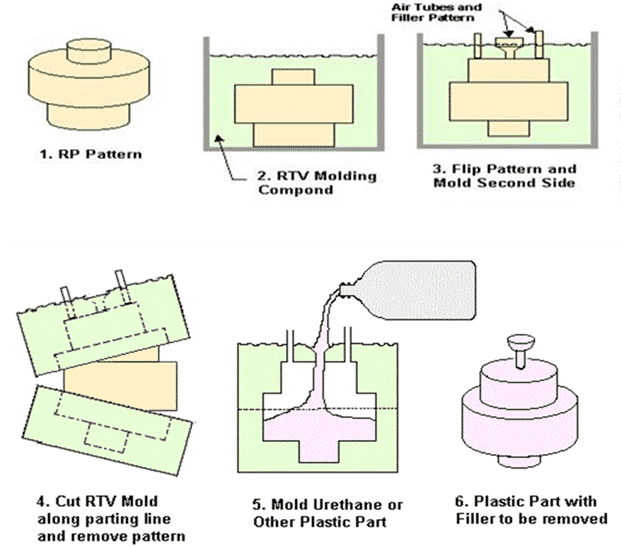

Resin and Polymer casting is a manufacturing process used to make copies of 3D objects or parts already in existence. The way this process works is that a mold is made, generally from a silicone material using the part being copied. Once the mold is made resins and polymers can then be poured into the mold making exact copies of the original part. Often times the process is great for making exact copies of 3D printed parts. Generally this process is used for low production and prototyping of parts.

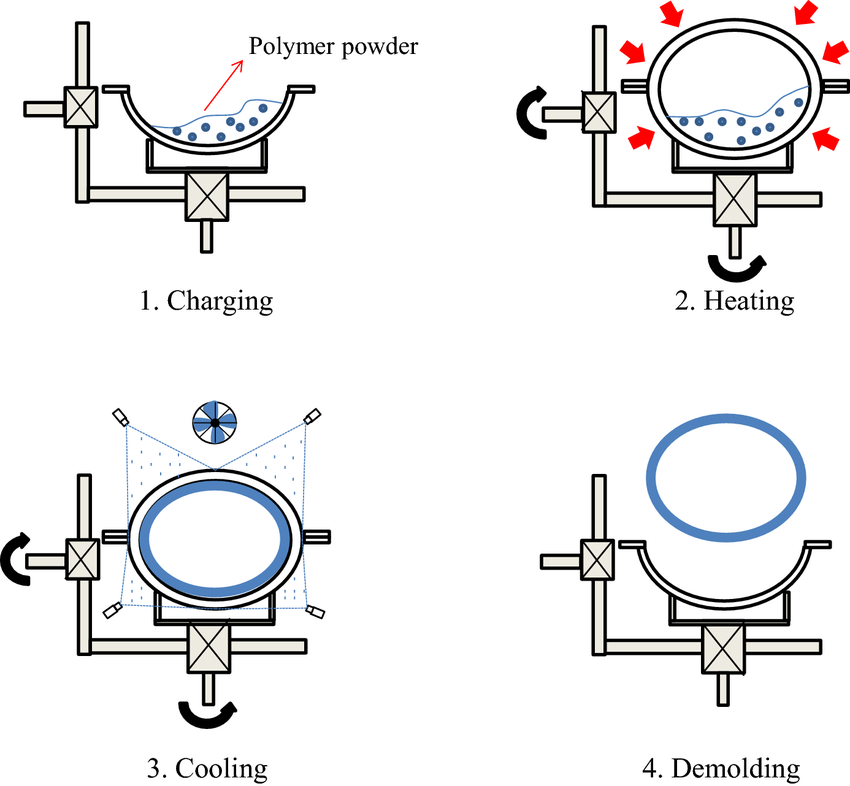

Rotational molding is the manufacturing process to form hollow cavity parts in all shapes and sizes. This is a cost-effective method to produce large hollow polymer parts. Polymers are added into a mold that’s heated and rotated slowly. The simultaneous heating and rotation distributes and fuses the resin on the inner surfaces of the mold. The result is a product that contains seamless parts with a uniform wall thickness with more material in corners to absorb shocks and stresses where they occur most.

With roto molding the part design has the freedom to be just about any shape and size. There is almost no limit to the size of moldings and there are literally thousands of applications.

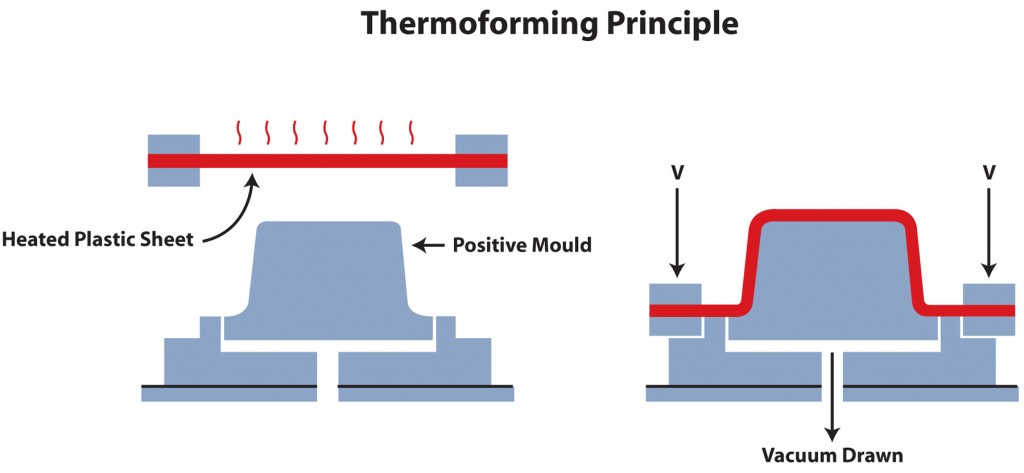

Thermoforming is the method of weakening a sheet of plastic by heating it to a certain temperature. The sheet is extended and controlled across a single-sided mold. Then it cools to its final shape. Vacuum-forming and pressure-forming are the most popular ways of getting the sheet to bend to its ultimate shape.

Thermoforming can be utilized in a variety of sectors and has a wide range of applications. The adaptability of thermoforming is one of its best features. This is seen in the wide range of materials that can be utilized in the procedure. Each material is ideally suited to certain applications and uses.

Blow molding is the manufacturing process that allows resins, plastics and polymers to be formed into shapes with hollow and internal cavities that a mold would not be able to be removed from. This process is most commonly seen in plastic bottles. The process works by placing a small preform or tube onto a nozzle like end that then heats the preform, at the same time air is blown into the preform and it expands the heated material to the shape of the surrounding mold.

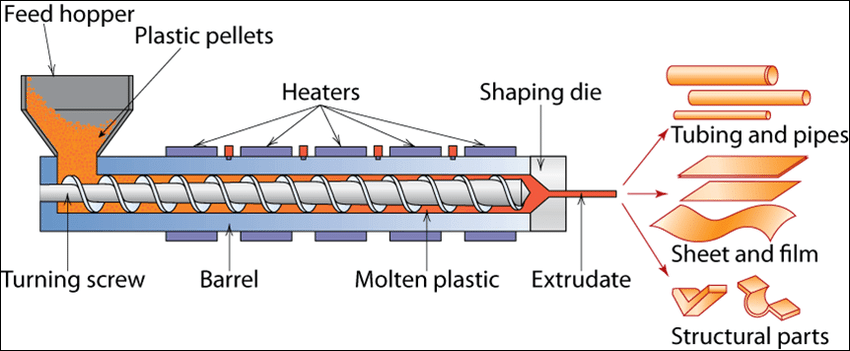

Plastic extrusion molding is a manufacturing process that allows resins, plastics and polymers to be formed into 2D profiles in specified lengths. The way this process works is that granules of raw material are fed through a screw feed system where they are heated, causing them to melt and at the same time are subject to hi-pressure. Once heated and under pressure the molten material is pushed through a die, forming the material to the shape of the die. The extrusions that are created can then be cut to various lengths and secondary finishes completed if required.

Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

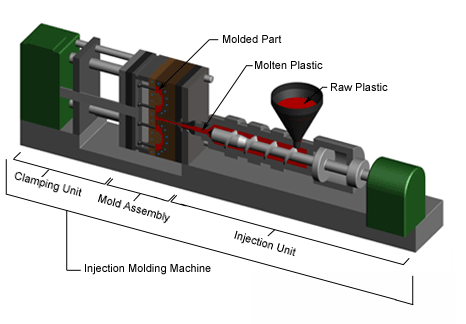

Plastic injection molding is the most commonly used manufacturing process for the production of small, medium, and large-sized plastic parts. The process utilizes an injection molding machine, raw plastic material, and a mold. The plastic is melted to molten by heating in the machine and then injected into the mold, where it cools and solidifies into the final part.

An injection molding machine is made up of a material hopper, barrel, an injection ram/rotating screw, heating device, moveable pattern, ejectors, and mold inside the mold cavity. Generally, machines work in a horizontal manner.

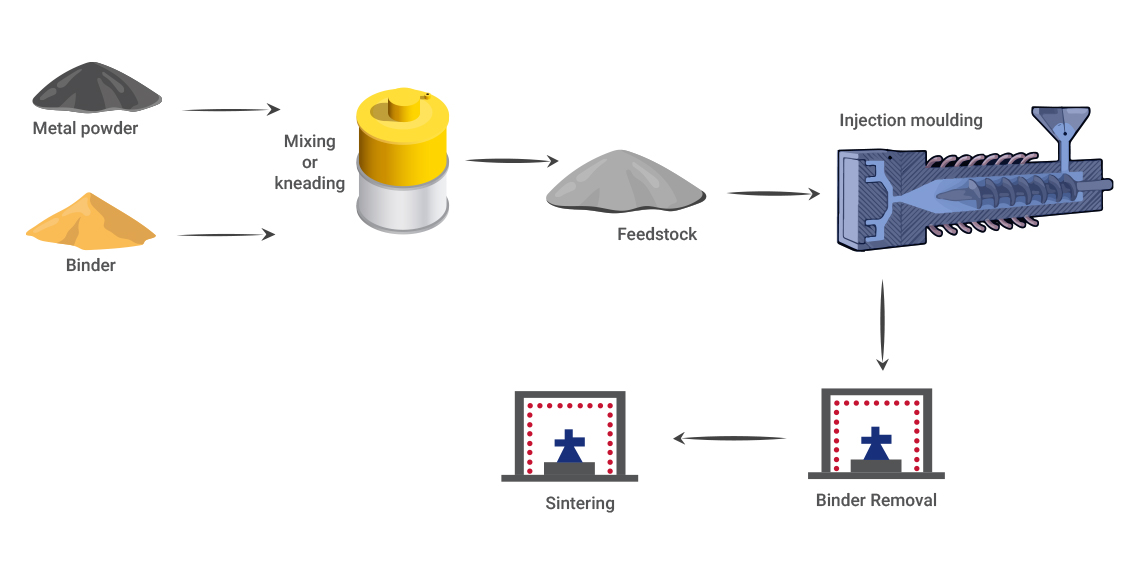

Metal Injection Molding (MIM) is a variation on traditional plastic injection molding that enables the fabrication of solid metal parts utilizing injection molding technology. In this process, the raw material, referred to as the feedstock, is a powder mixture of metal and polymer. Using a standard injection molding machine, the powder is melted and injected into a mold, where it cools and solidifies into the shape of the desired part. Subsequent heating processes remove the unwanted polymer and produce a high-density metal part.

Metal injection molding is best suited for the high-volume production of small metal parts. As with injection molding, these parts may be geometrically complex and have thin walls and fine details. Also, because the metal is not melted in the MIM process (unlike metal casting processes), high temperature alloys can be used without any negative affect on tool life.

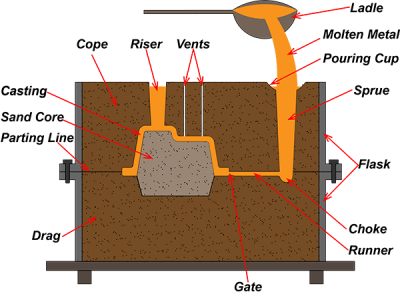

Metal casting is a modern process with ancient roots. In the metal casting process, metal parts are produced by pouring molten metal into a mold cavity, either made from a die or sand. In the mold the molten metal then cools and hardens in the shape of the mold and is later extracted. Metal casting is arguably the earliest and most influential industrial process in history. It’s used to make many of the metal objects used in our daily lives: automotive parts, train wheels, lamp posts and much more. Die casting is better suited for larger quantities of parts while sand casting is usually for smaller production runs.

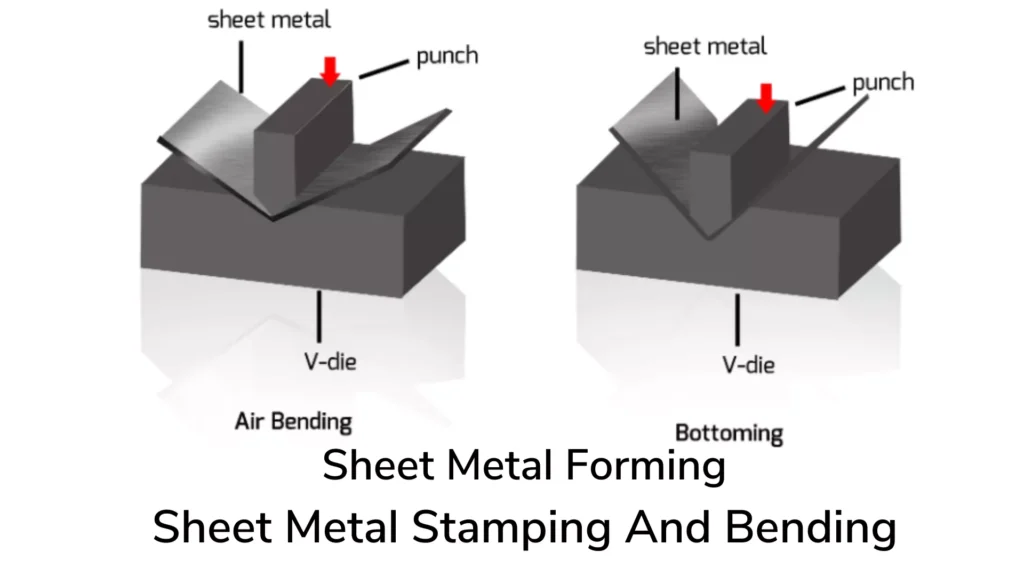

Metal bending is a process by which metal can be deformed when applying force or pressure to the subject, which causes it to bend at an angle and form the desired shape. The bending or shaping usually results in their being a ‘V’ or a ‘U’ shape where the bend is. The shaping is usually to a specific degree and there can be multiple bends in one part. One of the most common places metal bending can be seen is in metal enclosures for computers and electronics.

Metal laser cutting is a process which works by having a focused and precise laser beam trace trace an outline on the material that you are looking to cut, delivering an accurate and smooth finish. Initially, the beam pierces the material with a hole at the edge, and then the beam continues to cut by moving the beam precisely using CNC guidance. The laser essentially melts the material away that it is passing over. In this instance it is more like melting rather than cutting. This means laser cutting can easily cut light materials such as cloth up to tougher metals and gemstone. Once programmed, parts can be cut in a matter of seconds, much faster than the alternative methods of plasma or waterjet cutting.

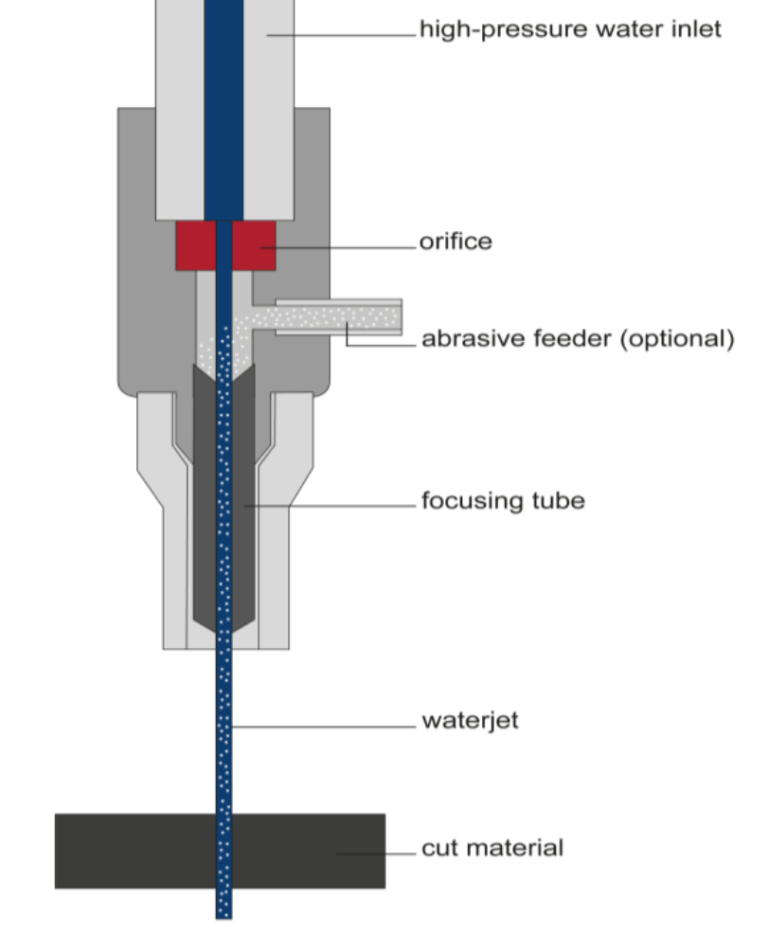

Water Jet cutting uses an ultra-high pressure stream of water to cut through a variety of materials. There are two main types of water jet cutting, pure water jet cutting and abrasive water jet cutting. In pure water jet cutting only pressurized water is used to cut materials. In abrasive water jet cutting, a gritty abrasive is added to the pressurized stream. The abrasive does the cutting through a mechanical sawing action, leaving a smooth, precision cut surface. Water jet cutting is one of the most versatile processes, because it is able to cut almost any type of material and the cost of material and setup is usually very minimal.

Waterjet machines cut all types of metals: hardened tool steel, aluminum, titanium, and a host of exotic metals that prove difficult to cut with other tools or processes. Cutting with a waterjet produces a smooth edge with no burn marks, cracking or excess burrs. In addition, since waterjet is a cold cutting method, there are no heat-affected zones.

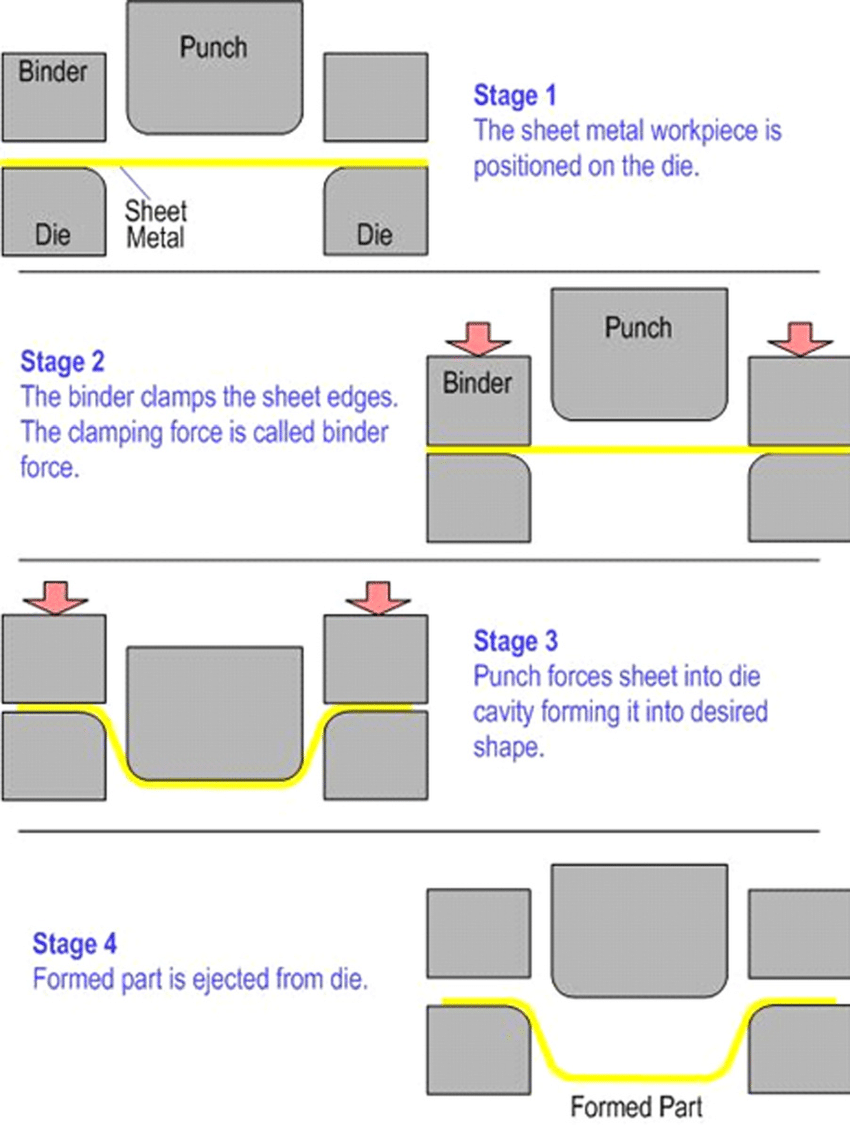

Metal stamping is a manufacturing process that involves the use of an industrial machine to deform/press a flat sheet of metal into a specific shape. Using pressure, the machine presses the sheet of material against a die surface. This changes the shape of the sheet metal to reflect that of the die surface, producing the desired part shape.

Metal stamping is an incredibly versatile and efficient manufacturing process that takes flat metal sheets or coils and transforms them into precisely shaped and intricate parts. By utilizing force, pressure, and specialized tooling, components with diverse forms — including bends, curves, cutouts, and embossing, are possible. This process offers low costs and dimensional stability

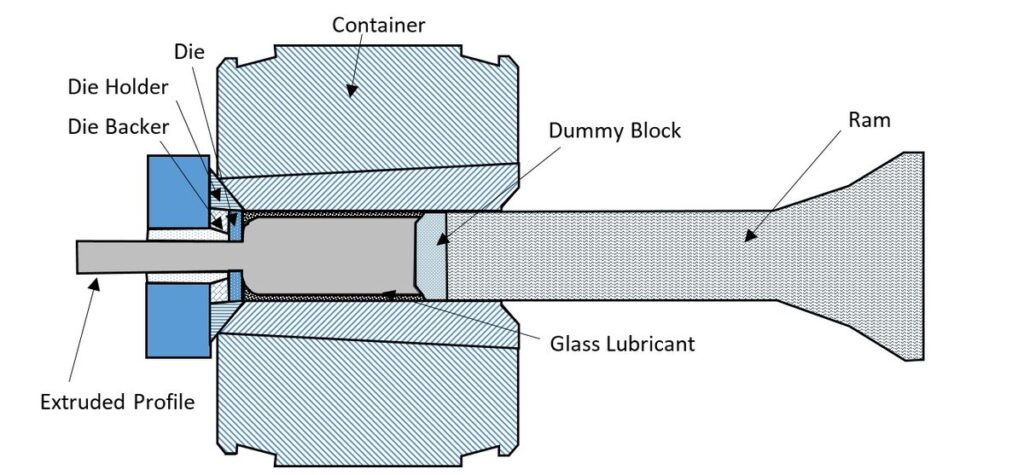

Metal extrusion is used to create lengths of metal of a fixed cross-sectional profile. Through extrusion, complex cross-sections can be created with excellent strength and surface finish. The process of aluminum extrusion works by forcing a block of metal, known as a billet, to pass through the die opening of smaller cross-sectional area than the billet itself. When the metal stock is heated and forced though the die, it is then shaped to the cross section of the die in desired lengths. This process is very accurate and produces little waste.

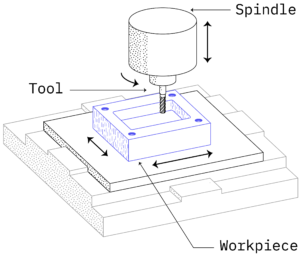

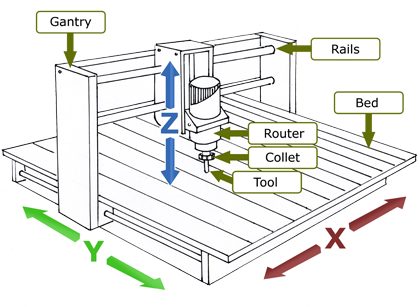

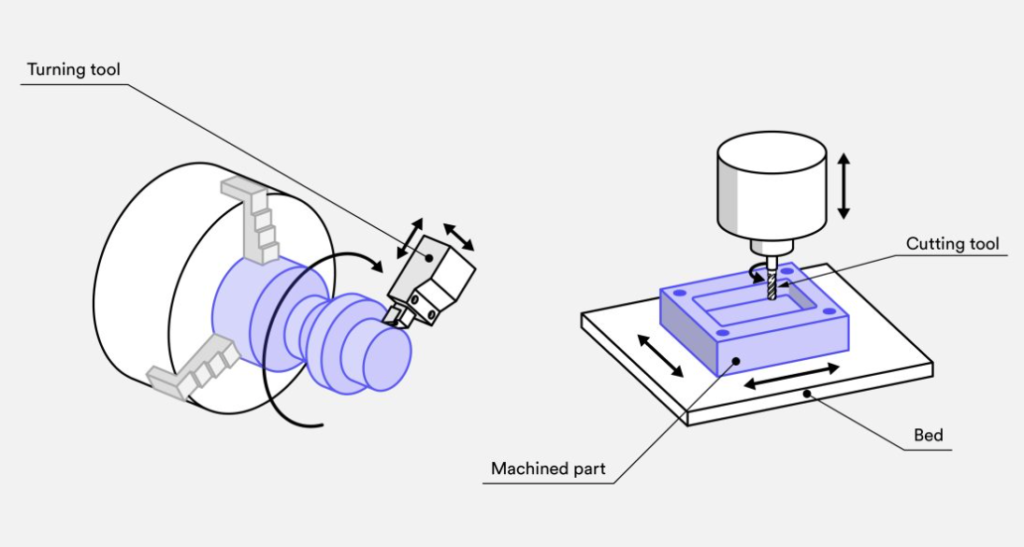

CNC Machining is a subtractive manufacturing method where in a piece of round or rectangular metal stock is started with and milled to the spec of the desired part. When working with square/rectangular stock the material is in a fixed position, usually in a vice or mounted to a jig and the platform it is on can move in the X and Y directions. The tool which is attached to the spindle can move vertically in the Z direction to cut and mill the pieces of raw material.

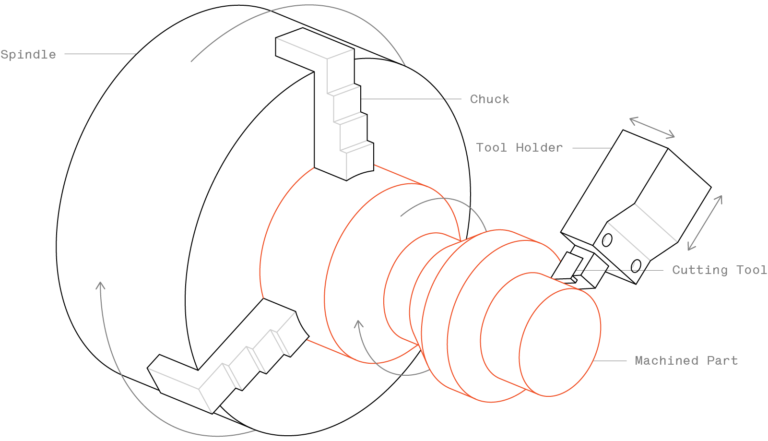

In CNC turning, the material is held in place by a chuck, which is attached to a spindle and the spindle turns the material at high revolutions per minute. The cutting tool which is stationary, then cuts and mills the turning piece of material.